We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for Treasure Garden,Teak Chairs Factory,Outdoor Conversation Set Manufacturer,Outdoor Bistro Chairs Supplier,Wholesale Teak Sectional Outdoor.We are sincerely looking forward to establishing good cooperative relationships with customers from at home and abroad for creating a bright future together. The product will supply to all over the world, such as Europe, America, Australia, Adelaide ,Oman ,Houston ,Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

I. Basic Information

Since its founding in 2003, SKSHU Paint Co., Ltd. (“3TREES”) has been committed to building healthy homes by providing an integrated 6-in-1 one-stop system of green construction materials and services, encompassing interior and exterior wall coatings, waterproofing products, insulation materials, auxiliary materials, floor coatings and construction. In 2016, 3TREES was listed on the A-share main board of the Shanghai Stock Exchange, becoming the first civilian paint company to get listed in China. Headquartered in Putian, Fujian Province, 3TREES has set up seven production bases in Tianjin, Chengdu, Nanyang, Chuzhou, Baoding and other places. More than 5,000 employees from all over the country work happily in this garden-like company. Characterized by its “Imitation of Nature” culture and with the beautiful eco-industrial park, the company has won the title of China’s Green Plant and was praised by leaders at all levels in China.

SKSHU Paint Co., Ltd. (Putian Plant) has annual designed production capacities are as follows: 10,300t/a alkyd resin, 1,500t/a acrylic resin 1,500t/a UV curable resin, 4,800t/a curing agent, 100,000t/a emulsion paint, 110,000t/a natural stone texture paint, 7,000t/a granite paint, 30,000t/a auxiliary materials, 30,000t/a wood paint and 25,000t/a adhesive, all of which has been completed and passed completion acceptance inspection. 3TREES’s Putian Plant covers an area of 174,186m2 or approximately 261mu.

Located in the Licheng Economic Development Zone of Putian City (within the factory area of SKSHU Paint Co., Ltd. (Putian Plant)), Fujian Sanjiang Packaging Co., Ltd. mainly produces tinplate packaging barrels. Its annual designed production capacities are as follows: 2.975 million 18L color barrels, 1 million 18L barrels, 1.134 million 5L round barrels, 1.134 million 4L round barrels, 4.5 million 2L barrels, 1.1592 million 1L square barrels, 2.4192 million 2L square barrels, and 2.4192 million 4L square barrels. The project covers an area of 14,150m2 or approximately 21.2mu.

Established in 2013, Tianjin SKSHU Paint Co., Ltd. (Tianjin Plant) currently rents industrial factory buildings in Shuangkou Town Industrial Zone, Beichen District, Tianjin. It has purchased corresponding production equipment and waste gas and sewage treatment facilities to produce emulsion paint, texture paint and granite paint. Its annual designed production capacities are as follows: emulsion paint: 20,000t/a; texture and granite paint: 30,000t/a; and putty powder: 10,000t/a. The project passed environmental acceptance inspection on October 25, 2014.

Established in 2015, Henan SKSHU Paint Co., Ltd. (Henan Plant) is located in the Nanzhao County Industrial Agglomeration Zone in Nanyang City, Henan Province. It currently rents industrial factory buildings, covering a total area of about 19,677m2. The plant mainly produces waterborne coatings and supporting materials. Its annual designed production capacities are as follows: 200,000 tons of waterborne coatings, and 3 million packaging barrels. The first-phase 100,000t/a waterborne coating project passed environmental acceptance inspection on August 29, 2017. The newly expanded phase II water-borne coating project with an annual output of 100,000 tons passed environmental acceptance inspection on October 29, 2018, and the 3 million packaging barrels project passed the environmental protection completion acceptance inspection on December 28, 2018.

Sichuan SKSHU Paint Co., Ltd. (Sichuan Plant), established in 2015, is located in Qionglai Industrial Park of Tianfu New Area in Chengdu, Sichuan Province. Covering a land area of 221,321.33m2 or approximately 331.982mu. it mainly produces coatings and auxiliary materials. Its current annual production capacities are as follows: 5,000 tons of curing agent, 30,000 tons of wood paint, 15,000 tons of water-based adhesives, 150, 000 tons of natural stone texture paint, 180,000 tons of emulsion paint, 90,000 tons of putty powder, 12 million packaging barrels, 10,000 tons of polyurethane waterproof paint, 800 tons of diatom mud, 3 million square meters of integrated thermal insulation boards, 20 million square meters of modified asphalt waterproof sheets with padding, 20 million square meters of modified asphalt waterproof sheets without padding, 7 million square meters of polymer waterproof sheets, and 5 million square meters of non-asphalt self-adhesive film waterproof sheets. Currently, all the production capacities have been completed and are undergoing acceptance inspection.

Anhui SKSHU Paint Co., Ltd. (Anhui Plant) was established in 2017. The planned plant within the red lines covers a land area of 250,685.5m2, with a total construction area of 169,000 m2. The plant mainly engages in the production and sales of coating, waterproof materials, new insulation materials, adhesives and other chemical products, as well as packaging materials. The company has invested in a coating production and supporting construction project in the Mingguang City Chemical Industry Agglomeration Zone, Anhui Province. Its current annual production capacities are as follows: 300,000 tons of emulsion paint, 200,000 tons of natural stone texture paint, 15,000 tons of waterproof paint, 20,000 tons of granite paint, 300,000 tons of putty powder, 40,000 tons of tile sealer, 5,000 tons of interfacial agent, 30 million cans, 10 million square meters of modified asphalt waterproof sheets with padding, 10 million square meters of modified asphalt waterproof sheets without padding, 1,800 million eco-boards, 30,000 tons of water-based adhesives and 60,000 tons of polyurethane waterproof paint. Currently, all the production capacities have been completed and are undergoing acceptance inspection.

II. Construction and Operation of Pollution Control Facilities

1. SKSHU Paint Co., Ltd. (Putian Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects, SKSHU Paint Co. Ltd. has improved its various environmental protection facilities to ensure stable and compliant emission. All its workshops are equipped with dedusting and degassing facilities. In the meantime, the company has also built a sewage treatment station, standardized solid waste storage site construction, and taken protective measures against wind, rain, leakage and loss. Its main environmental protection facilities include:

Waste gases generated in the company’s Wood Paint Workshops A and B, Adhesive Workshop and Resin Workshop are treated by pulse deposition dust removal + zeolite molecular sieve adsorption concentration runner + RTO regenerative combustion device, which can meet the requirements of Table 2 of Integrated Emission Standard of Air Pollutants (GB 16297-1996) and Table 4 of Emission Standard of Pollutants for Synthetic Resin Industry (gb31572-2015). Waste gases generated in emulsion, texture, granite and auxiliary material workshops are emitted according to the standard after collection by pulse-type precipitators. The precipitators mainly remove dust from the waste gases, reduce the emission of harmful substances such as particulate matter and meet the Grade II Standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB 16297-1996).

Domestic sewage in the plant area is directly discharged into the municipal pipe network after passing through a septic tank. It meets the Grade II Discharge Standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996) and the Grade B Standard of Wastewater Quality Standard for Discharge into Urban Sewers (GB/T31962-2015). Production wastewater is discharged into the comprehensive sewage treatment station in the plant area after being treated by the pretreatment station. The sewage stations adopt a combination of physicochemical and biochemical methods to ensure stable treatment effect and high pollutant removal rate. Production wastewater discharge meets the Grade III Standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996). After entering the municipal sewage pipe network, production wastewater is brought to the Minzhong Sewage Treatment Plant for further treatment. Currently, the company has a resin organic wastewater treatment system to treat high concentration organic wastewater in accordance with the Discharge Standard of Pollutants for Synthetic Resin Industry (GB31572-2015). However, following a product structure adjustment, the company has stopped resin production, and the system was put out of service in July 2019.

To eliminate the impact of the noise inside the plant on outside residents, various measures have been taken in the workshops/factory buildings that are prone to cause big noise. For example, low-noise facilities and sound insulation doors are adopted for air compressor equipment to reduce noise. Thanks to these measures, noise at the boundary of the plant meets the Type III limit values of Emission Standard for Industrial Enterprises Noise at Boundary (GB 12348-2008).

Through the above-mentioned environmental protection measures, the treated sewage, waste gases and noise at SKSHU Paint Co., Ltd. have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

2. Fujian Sanjiang Packaging Co., Ltd.

In strict accordance with the "Three Concurrents" requirements for construction projects, Sanjiang Packaging has improved its various environmental protection facilities to ensure stable and compliant emission. Its workshops are equipped with 3 gas collection systems, and gas emission meets the Grade II Standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Through the above-mentioned environmental protection measures, the treated waste gases at Sanjiang Packaging have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

3. Tianjin SKSHU Paint Co., Ltd. (Tianjin Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects, Tianjin SKSHU has improved its various environmental protection facilities to ensure stable and compliant emission. Waste gases generated in the production workshops are treated by submerged filter cartridge dust removal device and photocatalyst waste gas purifier, which meets the Grade II Standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB16297-1996).

Production wastewater is treated by the "physicochemical + biochemical" treatment process through the sewage treatment station in the plant area, and is discharged after reaching the Grade III standard of Integrated Wastewater Discharge Standard (D12/356-2008). After entering the municipal sewage pipe network of the industry park, the production sewage is finally discharged into the Shuangqing Sewage Treatment Plant for centralized treatment.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Tianjin SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

4. Henan SKSHU Paint Co., Ltd. (Henan Plant)

In strict accordance with the "Three Concurrrents" requirements for construction project, Henan SKSHU has built various environmental protection facilities to ensure stable and compliant emission. Waste gases generated in the production workshops are discharged after being treated by bag filter + photocatalysis + activated carbon adsorption, and meet the Grade II standard in Table 2 of Integrated Emission Standard of Air Pollutants (GB 16297-1996).

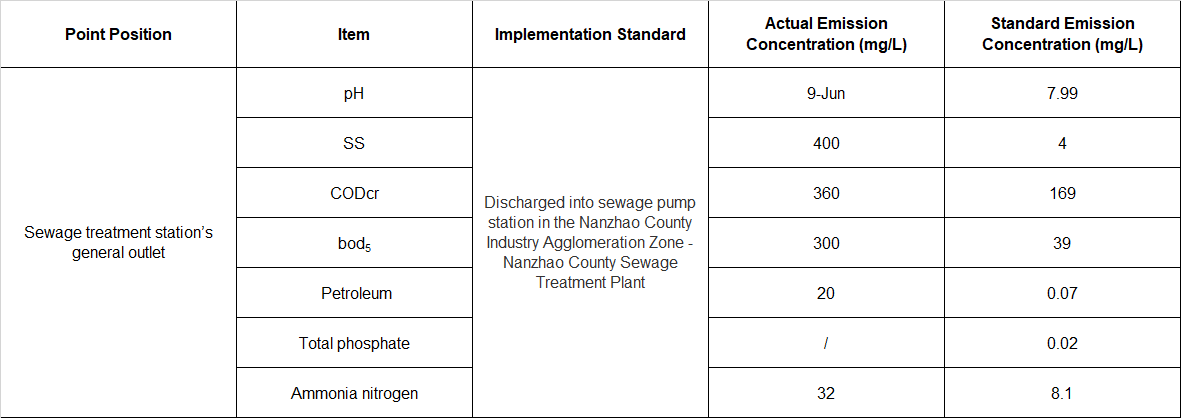

Production wastewater is treated by the "physicochemical + biochemical" treatment process through the sewage treatment station in the plant area, and discharged into the Nanzhao County Sewage Treatment Plant for centralized treatment. It meets the discharge standard of the inlet sewage pipe network of the Nanzhao Sewage Treatment Station.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Henan SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

5. Sichuan SKSHU Paint Co., Ltd. (Sichuan Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects and its EIA report, Sichuan SKSHU has built various environmental protection facilities. Dust-containing gases generated in the water-based workshops are discharged up to the standard after being treated by submerged filter cartridge dust collectors. Dust-containing organic waste gases generated in the oil-based workshops are pretreated by submerged filter cartridge dust collectors, and then pass through molecular sieve adsorption concentration runner + RTO thermal storage combustion device. The waste gas treatment facilities meet the requirements of Integrated Emission Standard of Air Pollutants (GB16297-1996), Emission Standard of Sichuan Province for Atmospheric Volatile Organic Compounds from Fixed Pollution Sources (DB51/2377-2017) and Emission Standard of Odor Pollutants (GB14554-93)

Production wastewater and domestic sewage in the plant area are treated by the sewage treatment station in the plant area. Production wastewater is firstly treated by "high efficiency air flotation + micro electrolysis", and then by "anaerobic biological filter + biological contact oxygen" along with the domestic sewage. After reaching the Grade III Standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996), production wastewater enters Qionglai City No.3 Wastewater Treatment Plant through the municipal sewage pipe network for treatment, before being discharged into the Xiajiang River.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Sichuan SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

6. Anhui SKSHU Paint Co., Ltd. (Anhui Plant)

In strict accordance with the "Three Concurrents" requirements for construction projects and its EIA report, Anhui SKSHU has built various environmental protection facilities. Following pulse filter + UV photolysis + secondary activated carbon adsorption treatment, waste gases generated in the production of emulsion, granite, natural stone texture paints and sample boards at the comprehensive workshops can reach the Grade II Emission Standard of Integrated Emission Standard of Air Pollutants (GB 16297-1996), the emission limits of Table 1 of Emission Standard of Volatile Organic Compounds Part 6: Organic Chemical Industry and Table 1 of Emission Standard of Volatile Organic Compounds Part 7: Other Industries. Waste gases generated in the production of polyurethane waterproof coating, water-based adhesives and Phase II thermal insulation integrated boards are collected for pulse dust removal treatment, while VOCs are treated by "molecular sieve runner + RTO thermal storage combustion" to meet the requirements of Table 5 Special Emission Limits of Air Pollutants of Emission Standard for Pollutants in Synthetic Resin Industry (631572-2015), the special emission limit requirements of Emission Standard of Air Pollutants for Cement Industry (GB4915-2013), and the emission limits in Table 1 of Emission Standard for Volatile Organic Compounds Part 7: Other Industries. Waste gases generated in the production of asphalt waterproofing rolls are treated by oil spray absorption tower washing + double-layer electrostatic capture + filter filtration + UV photodegradation to meet the Time Period II standard limit requirements of Emission Standard Of Air Pollutants for Waterproofing Roll Industry (DB11/1055-2013). Waste gases generated from the sewage treatment station are treated by spray tower + photocatalytic oxidation device to meet the requirements of Emission Standard for Odor Pollutants (GB 14554-93).

Production wastewater is pretreated by the sewage treatment station in the plant area, and domestic sewage enters the sewage treatment station in the plant area for treatment by using "grid + primary sedimentation + flocculation sedimentation + micro electrolysis + biological anaerobic + biological contact oxidation + secondary sedimentation tank + mixed flocculation + aerated active filter tank" processes. Wastewater from the treatment of polyurethane waterproof coating and water-based adhesives is treated to meet Discharge Standard of Pollutants for Synthetic Resin Industry (GB31572-2015). Sewage discharged from the plant enters the Chengdong Sewage Treatment Plant through the municipal sewage pipe network.

Through the above-mentioned environmental protection measures, the treated sewage and waste gases at Anhui SKSHU have reached the emission standards specified in the EIA written reply document. All environmental protection facilities can operate stably, and the synchronous operation rate of the facilities meets the requirement.

III. Type, Quantity and Destination of Discharged Pollutants

1. Type, Quantity and Destination of Pollutants Discharged by SKSHU Paint Co., Ltd. (Putian Plant)

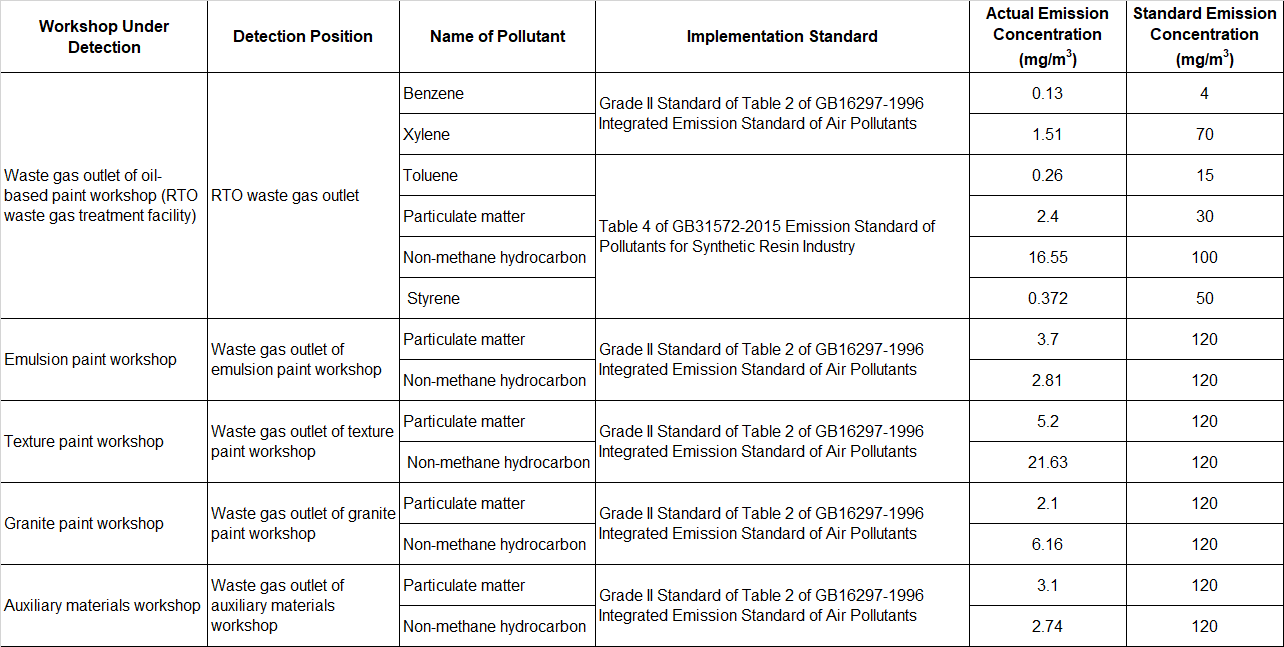

(1) The main pollutants of waste gas emissions include: non-methane hydrocarbon, benzene, toluene, xylene, particulate matter, etc.

Note: Data source - test report of Fujian Zhongkai Detection Technology Co., Ltd. on September 17, 2019 (No.: ZK191090225).

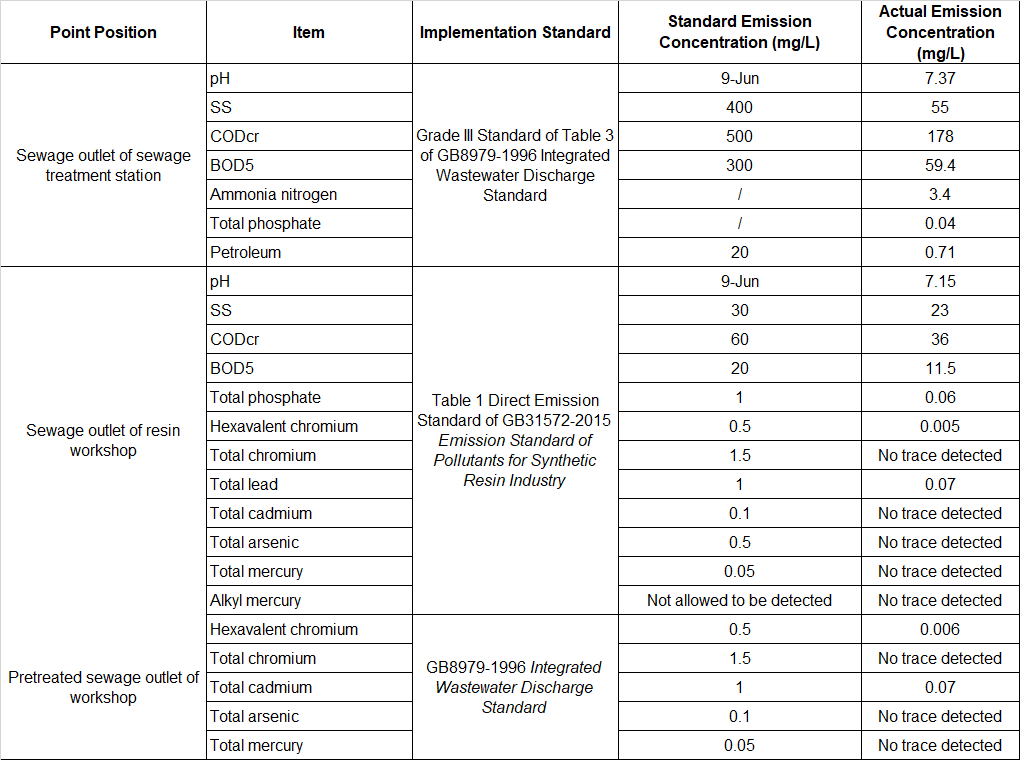

(2) After treated by the company's sewage treatment station, sewerage is discharged into the municipal sewage pipe network and then the Minzhong Sewage Treatment Plant for centralized treatment.

Note: Data source - the test reports of Fujian Zhongkai Detection Technology Co., Ltd. on July 19, 2019 (No.: ZK19070212) and September 17, 2019 (No.: ZK191090225).

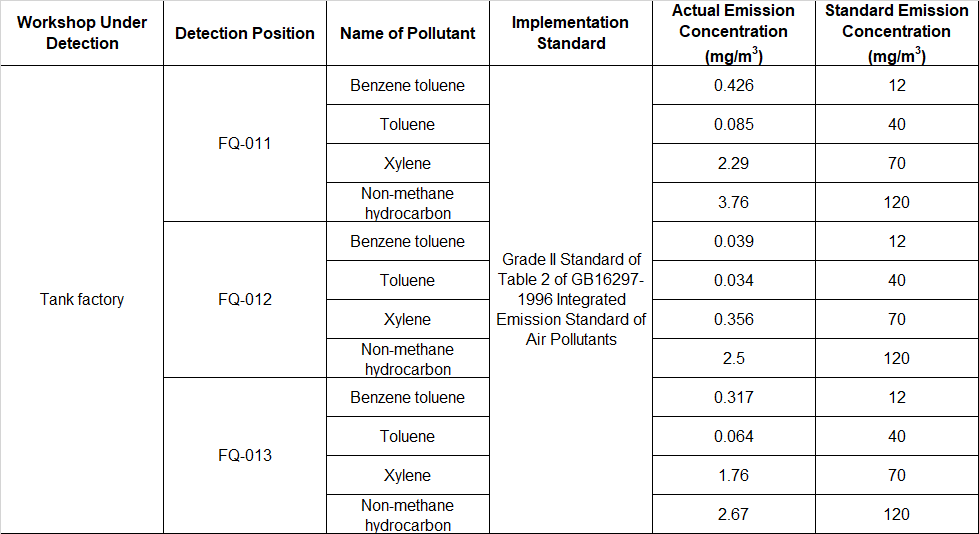

2. Types, Quantity and Destination of Pollutants Discharged by Fujian Sanjiang Packaging Co., Ltd,

The main pollutants of waste gas emissions include: non methane hydrocarbon, benzene, toluene and xylene.

Note: Data source - test reports of Fujian Zhongkai Detection Technology Co., Ltd. on August 17, 2019 (No.: ZK19080215) and September 18, 2019 (No.: ZK191090226).

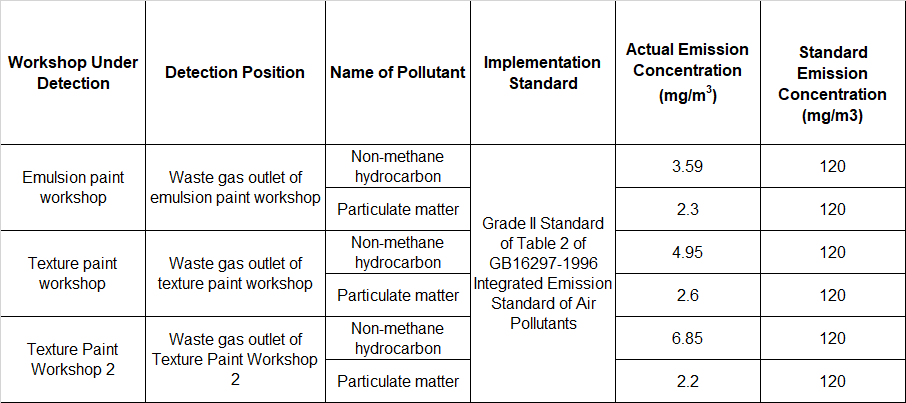

3. Type, Quantity and Destination of Pollutants Discharged by Tianjin SKSHU Paint Co., Ltd. (Tianjin Plant)

(1) The main pollutants of waste gas emissions include non-methane hydrocarbon and particulate matter.

Note: data source - the test report of Tianjin Sanfang Testing Center Co., Ltd. on November 27, 2019 (No.: Jin San Fang Jian (Wei) 1-201911-036).

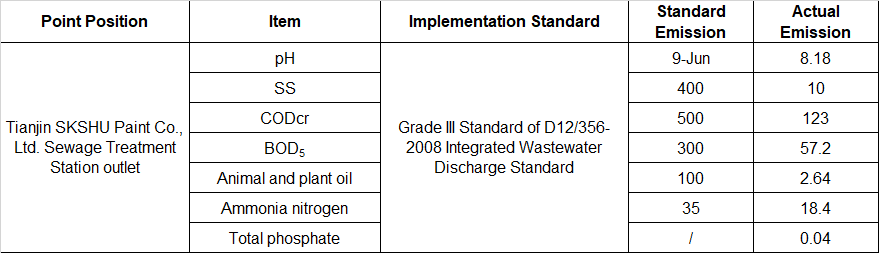

(2) After treatment by the company's sewage treatment station, sewage is discharged into the municipal sewage pipe network and then into the Shuangqing Sewage Treatment Plant for centralized treatment.

Note: data source - the test report of Tianjin Sanfang Testing Center Co., Ltd. on November 27, 2019 (No.: Jin San Fang Jian (Wei) 1-201911-036).

4. Types, Quantity and Destination Of Pollutants Discharged by Sichuan SKSHU Paint Co., Ltd. (Sichuan Plant)

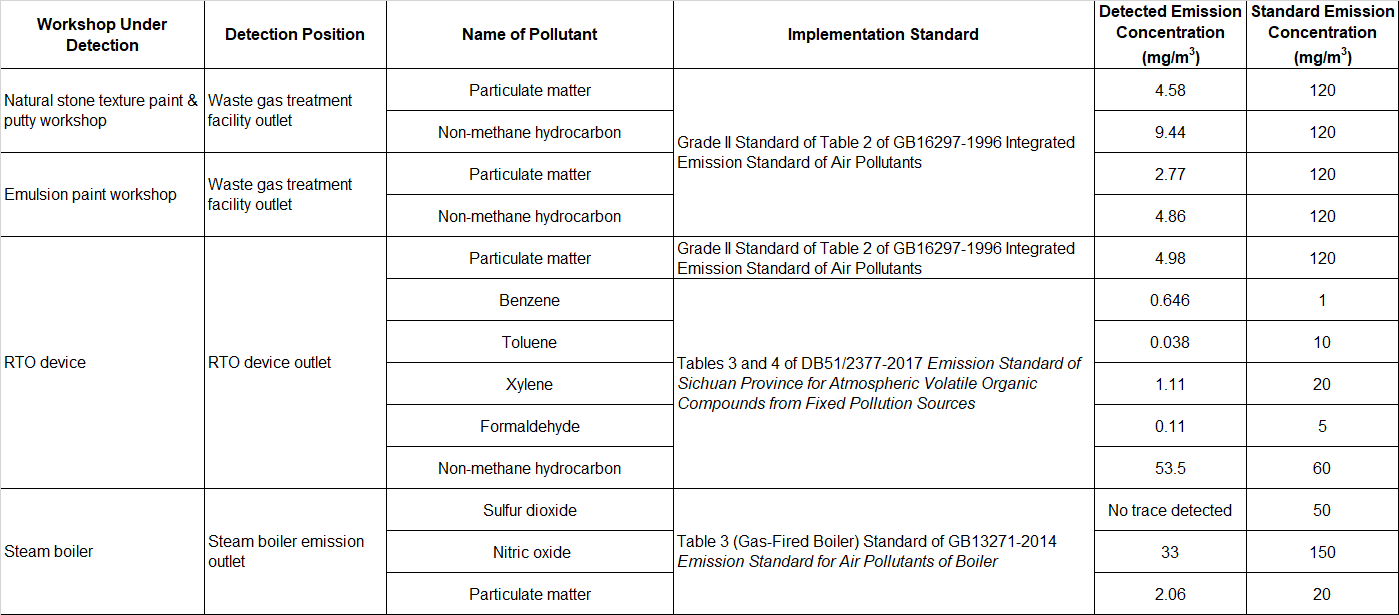

(1) The main pollutants of exhaust gas emissions include non-methane hydrocarbon and particulate matter.

Note: data source - the test report of Sichuan Kaile Detection Technology Co., Ltd. on March 26, 2019 (No.: Kai Le Jian Zi (2019) No.03416W).

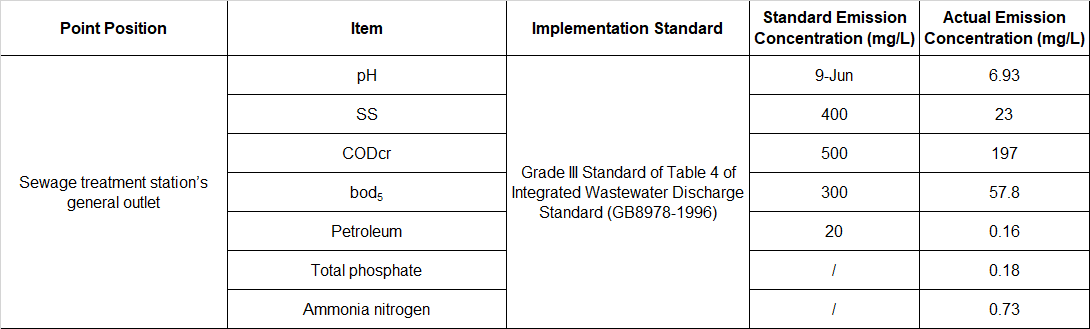

(2) After treatment by the company's sewage treatment station, sewage is discharged into Qionglai No.3 Sewage Treatment Plant for treatment through the municipal pipe network.

Note: data source - the test report of Sichuan Kaile Detection Technology Co., Ltd. on March 26, 2019 (No.: Kai Le Jian Zi (2019) No.03416W).

5. Type, Quantity and Destination of Pollutants Discharged by Henan SKSHU Paint Co., Ltd. (Henan Plant)

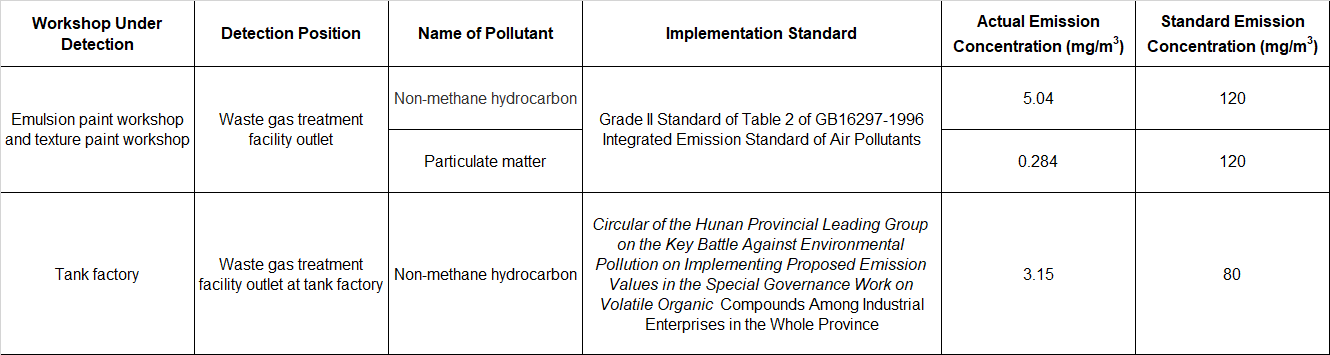

(1) The main pollutants of exhaust gas emissions include non-methane hydrocarbon and particulate matter.

Note: data source - the test report of Henan Micron Detection Technology Co., Ltd. on October 22, 2019 (No.: WMJC [2019] No. 0923-E04).

(2) After treatment by the company’s sewage treatment station, sewerage is discharged into the sewage pump station in the Nanzhao County Industry Agglomeration Zone and finally the Nanzhao County Sewage Treatment Plant after centralized treatment.

Note: data source - the test report of Henan Micron Detection Technology Co., Ltd. on October 22, 2019 (No.: WMJC [2019] No. 0923-E04).

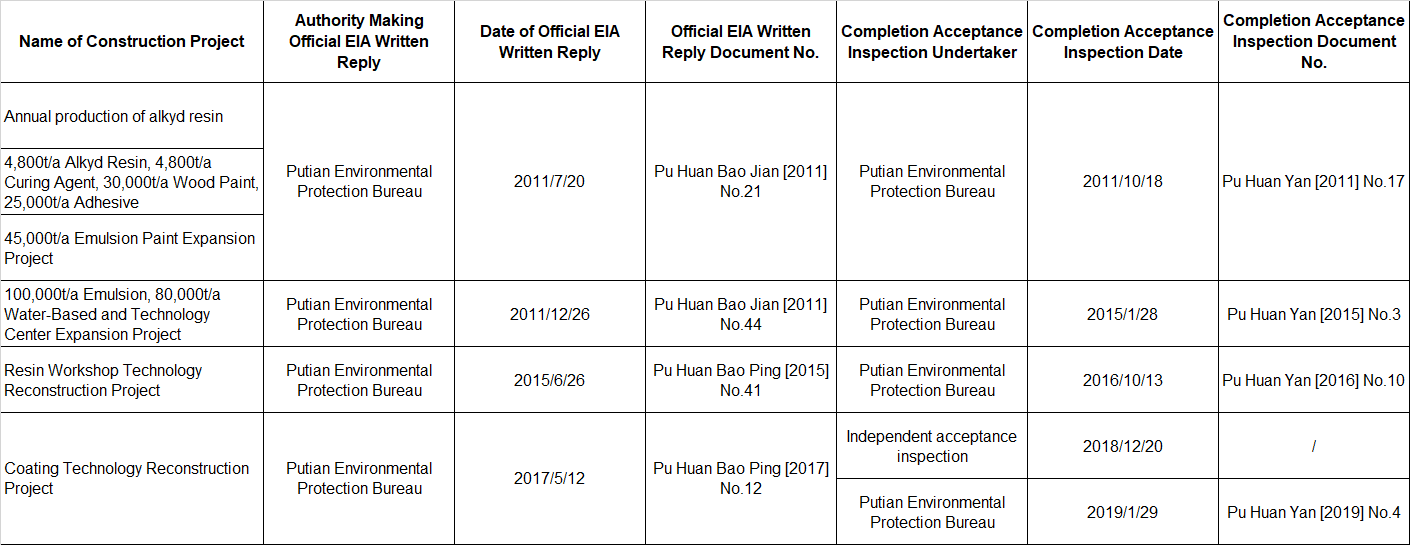

IV. Construction Project EIA and Other Administrative Permits for Environmental Protection

1. SKSHU Paint Co., Ltd.

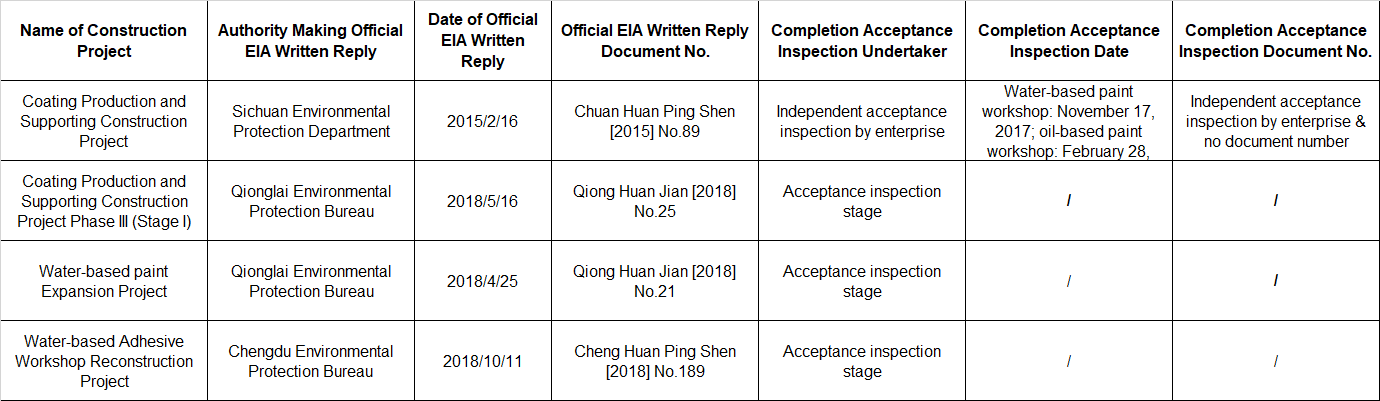

2. Sichuan SKSHU Paint Co., Ltd.

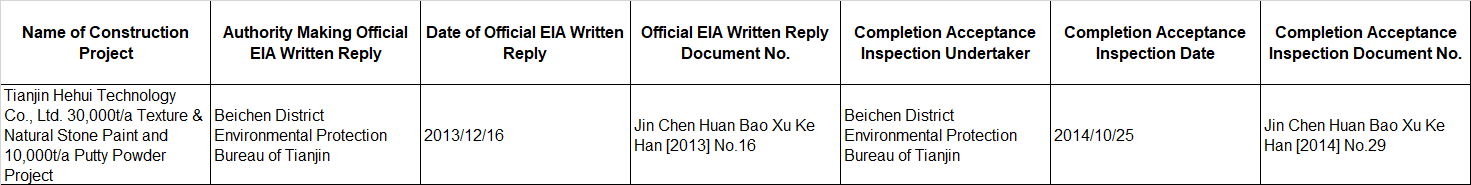

3. Tianjin SKSHU Paint Co., Ltd.

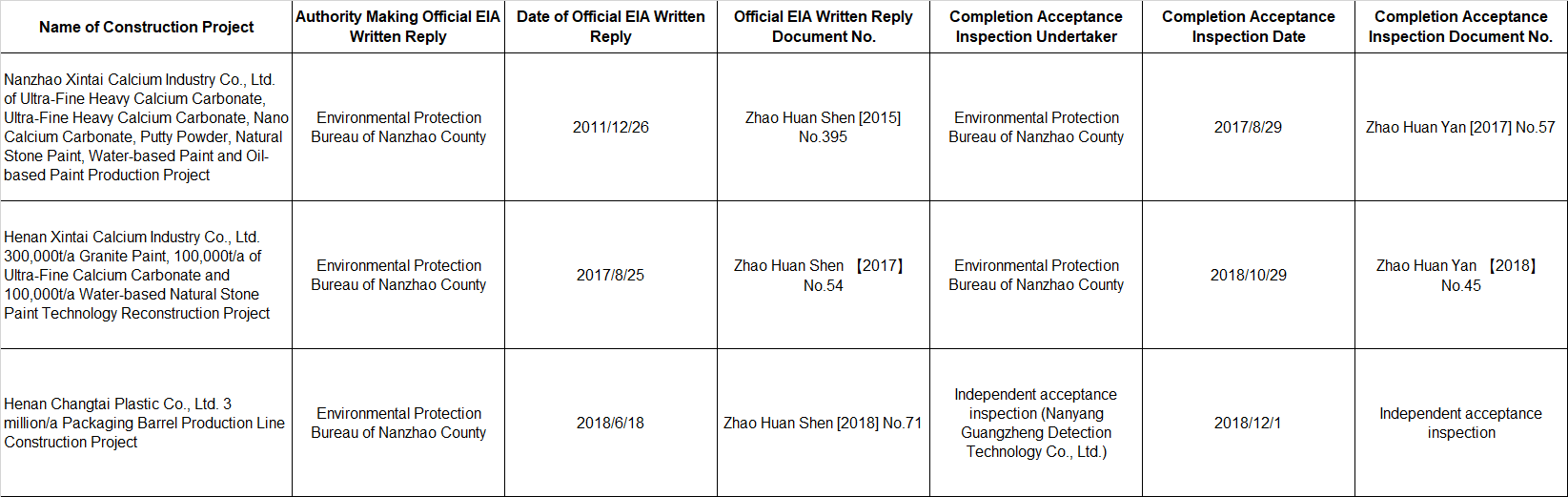

4. Henan SKSHU Paint Co., Ltd.

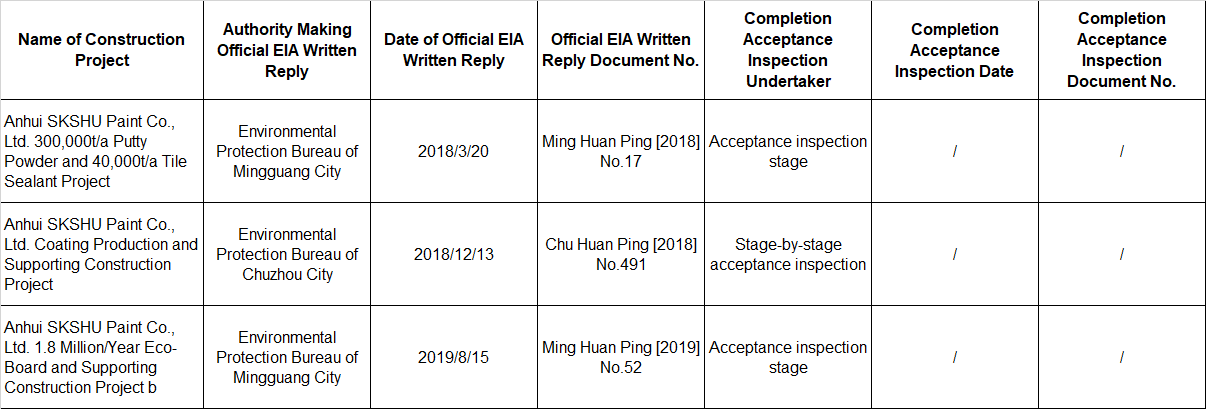

5. Anhui SKSHU Paint Co., Ltd.

V. Contingency plan for environmental emergencies

All factories of the 3TREES Group have compiled their Contingency Plans for Environmental Emergencies, which have been reviewed by experts and reported to local bureaus of ecology and environment for filing.

The contingency drills organized by various 3TREES plants in 2019 mainly include:

In June 2019, 3TREES (Putian Plant) held a contingency rescue drill on solvent dispersion kettle leakage in wood paint workshop.

In September 2019, 3TREES (Tianjin Plant) organized an emulsion barrel leakage accident drill.

In October 2019, 3TREES (Henan Plant) organized an emulsion barrel leakage contingency drill.

In May 2019, 3TREES (Henan Plant) organized a corrosive additive barrel breakage contingency drill.

In April 2019, 3TREES (Sichuan plant) organized a raw material leakage contingency drill.

The home carries our yearning for a better life. 3TREES cares about the well-being of society at large, as well as the health of individual families. Carrying forward its original aspiration of “making homes healthier and cities more beautiful” and adopting a twin-driver strategy of innovation and service, and thanks to its internationally advanced quality control, lean production and fine supply chain management, 3TREES has become the first in China’s coating industry to develop 3TREES BB Paint, an innovative “Food Contact Grade” wall paint, using “Food Contact Grade” emulsion as the core raw material.

The 3TREES BB Paint passes through four key controls through Food Contact raw materials, Food Contact Grade innovative formula, safe and pollution-free production environment, and traceable production management. These strict quality controls ensure the top quality of the 3TREES BB Paint. In the meantime, the product has also successfully passed the Food Contact Grade standard test (FDA21CFR175.300) formulated by the US Food and Drug Administration (FDA).

What is FDA and “Food Contact Grade”?

FDA is currently the most authoritative audit body in the international food and medical industry.

FDA's standards are known as the most authoritative food contact health and safety standards in the world. Products that pass FDA's standard tests reach the "Food Contact Grade" safety level.

"Food Contact Grade" Safety Index: refers to that harmful substances reach the low level of transfer in the process of contact with food, which meets FDA's relevant safety standard. Common materials that should meet the requirements of the Food Contact Grade standard are: packaging and coatings, tableware materials and coatings, infant supplies materials and coatings, etc. which are in contact with food.

Multiple environmental certifications ensure green quality

Besides passing FDA’s relevant standard tests, the 3TREES BB Paint has also won multiple environmental certifications, including UL GREENGUARD Gold Certification, French Indoor Air Emissions A+ Certification, and China Green Product Certification. Featuring skin-friendly, antibacterial, odorless and free of additives, and passing tests with tens of thousands of scrubs, the 3TREES BB Paint is a safe and guaranteed green product.

From "Health" to "Health +", the ideas of health advocated by 3TREES are built on solid rules and standards. From Chinese, US and EU certifications to German Blue Angel Certification and then Food Contact Grade Certification, all the products made, upgraded and prompted by 3TREES are of the best quality possible. Since its establishment, 3TREES has pioneered in innovation and achieved frog-leap development, driven by its corporate mission of "making homes heathier and cities more beautiful".

In the future, 3TREES will continue to carry the banner of a big country brand, adhere to the path of green, sustainable and high-quality development path with big brands, good products and good services, create a better life for mankind, and strive to realize the great vision of serving the country through brand and greening the world.

I. Basic information

SKSHU Paint Co., Ltd. (hereinafter referred to as "3TREES") is located in Licheng Economic Development Zone, Putian City as the industrial zone is situated in the center of Hanjiang and Licheng Districts where the main roads such as Fuxia Road, South Shaolin Road and Lihan Avenue form a checkerboard road network with convenient transportation. 3TREES is bordered by Dongchuan Road in the north, a land for other industrial purposes in the Zone in the south, Donghu Road in the east, and Jiaozhan West Road in the west, i.e. 3TREES is at 25.47 north latitude and 119.04 east longitude. Its address is 518 Liyuan North Avenue, Putian City, Fujian Province, its legal representative is Hong Jie, and its unified social credit code is 91350300751385327E. The contact phone number is 400-8823-777/800-8584-333.

The business of SKSHU Paint Co., Ltd. covers production and sales of coatings, adhesives, emulsions, curing agents, daily chemicals and other chemical auxiliary materials, and technical testing services.

The designed annual output of SKSHU Paint Co., Ltd. (Putian factory) is 10,300t/a of alkyd resins, 1,500t/a of acrylic resins, 1,500t/a of light-cured resins, 1,500t/a of unsaturated resins, 4,800 t/a of curing agents, 327,000 t/a of water-based coatings, 30,000 t/a of wood paints and 25,000 t/a of adhesives. The SKSHU Paint Co., Ltd. (Putian Factory) covers an area of 174,186m2.

Fujian Sanjiang Packaging Co., Ltd. is located in Licheng Economic Development Zone, Putian City (within SKSHU Paint Co., Ltd. (Putian Factory)), which mainly produces tinplate packaging cans with a designed annual output of 2.975 million cans of 18L round buckets, 1 million cans of 18L square buckets, 1.134 million 5L round cans, 1.134 million 4L round cans, 4.5 million 2L round cans, 1.1592 million 1L square cans, 2.4192 million 2L square cans and 2.4192 million 4L square cans. And the project covers an area of 14,150m2.

Tianjin SKSHU Paint Co., Ltd. (Tianjin Factory) was established in 2013, renting an existing industrial plant in Shuangkou Town Industrial District, Beichen District, Tianjin, with purchased production equipment and waste gas and sewage treatment facilities to produce latex paints, texture paints and natural stone paints. And its annual output designed is 20,000 tons of latex paints, 30,000 tons of texture paints and natural stone paints, and 10,000 tons of putty powder. The project passed the environmental protection approval on October 25, 2014.

Henan SKSHU Paint Co., Ltd. (Henan Factory), established on March 22, 2016, is located in the industrial clustered area of Nanzhao County, Nanyang City, Henan Province with a rented industrial plant of about 19,677㎡, and is mainly engaged in the production of water-based coatings and accessories. Its annual output designed is 200,000 tons of water-based coatings and 3 million packaging tanks. Also, the first phase of the 100,000-ton water-based coating project passed the environmental protection approval on August 29, 2017. The newly expanded phase II project for water-based paints with an annual output of 100,000 tons passed environmental protection assessment and approval on October 29, 2018, and the project with an annual output of 300 packaging buckets passed the approval on December 28, 2018.

Sichuan SKSHU Paint Co., Ltd. (Sichuan Factory) was established on April 9, 2015 and located in Qionglai Industrial Park, Tianfu New District. The total area is about 221,321.33m2, and is mainly engaged in the production of coatings and accessories. The annual output designed include 5,000t of alkyd resins, 5,000t of curing agents, 30,000t of wood paints, 15,000t of water-based adhesives, 50,000t of natural stone and texture paints, 60,000t of emulsion paints, 30,000t of putty powders, 12 million packaging tanks, 10,000t/a of polyurethane waterproof coatings, 3 million ㎡/a of integrated boards, 20 million ㎡/a of modified asphalt waterproofing membranes with base, 7 million ㎡/a of polymer waterproofing membranes and 5 million㎡/a of non-asphalt self-adhesive waterproofing membranes. And the alkyd resin production line has not been built yet, polyurethane waterproofing coating, integrated board and waterproofing membrane production lines are under construction, and other production lines have been completed and approved.

Anhui SKSHU Paint Co., Ltd. was established in November 2017 and is mainly engaged in the production and sales of coatings, waterproof materials, new insulation materials, adhesives and other chemical products and packaging materials. And the company has invested in the construction of paint producing and supporting projects in Mingguang City Chemical Industry Concentration Zone, Anhui Province. Upon completion, it could achieve an annual output of 300,000 tons of latex paints, 200,000 tons of natural stone and texture paints, 15,000 tons of waterproof paints, 20,000 tons of granite paints, 300,000 tons of putty powders, 40,000 tons of tile adhesives, 5,000 tons of interface agents, 30 million cans, 20 million square meters of modified asphalt waterproofing membranes with base, 14 million square meters of polymer waterproofing membranes, 30,000 tons of water-based adhesives, 60,000 tons of polyurethane waterproofing coatings and other products. Now the project is under construction.

II. The Construction and Operation of Pollution Control Facilities

1. SKSHU Paint Co., Ltd. (Putian Factory)

Acting in strict accordance with the "Three Simultaneities" requirements for construction projects, the company has enhanced its environmental protection facilities to ensure the stable and qualified discharge of various environmental factors. The workshops are equipped with dust removal and degassing facilities, sewage treatment stations are established, solid waste storage yards are up to the standards, and measures such as wind and rain protection, leakage and loss prevention are taken. The main environmental protection facilities are:

(1) VOC treatment and dust removal devices: In wood paint A and B workshops, and adhesive and resin workshops, pulse sedimentation dust removal and zeolite runner RTO combustion devices are adopted to treat organic waste gas; the solvent for which is adsorbed in the gap of zeolite runners through the porosity of zeolite runners and the tension of the gap surfaces so that the discharged waste gas is purified. When zeolite wheels are saturated with the solvent, the latter is desorbed and regenerated by hot air, and the detached organic matter is oxidized at a high temperature to convert the organic waste gas into carbon dioxide and water. In latex paint and texture paint workshops, sedimentation dust removal devices are used to remove dust in waste gas and reduce the emission of harmful substances such as particles in the gas.

(2) Sewage treatment stations: waste water from reactor cleaning, workshop floor washing and laboratory as well as sanitary sewage from workshop employees is treated by the existing sewage treatment stations, discharged into the municipal sewage pipe network after measuring up to the standard, and merged into Minzhong Waste Water Treatment Plant for further treatment. And at the sewage treatment stations is adopted a combination of physical and biochemical treatment as well as processes of grid filtering, sedimentation and biological contact oxidation of stable treatment effect and high pollutant removal rates. Resin organic waste water treatment is done by a set of sewage treatment equipment (catalytic micro-electrolysis devices, ultra-high load integrated bio-reactors, circular biological reaction devices, up-flow anaerobic filters, photo-Fenton oxidation devices, hydrolysis devices, flocculation precipitator, etc.). Upon reaching the standard, the waste water is discharged into the municipal sewage pipe network and merged into Minzhong Waste Water Treatment Plant for further treatment.

These environmental protection measures have enabled the company to meet the emission standards approved by EIA in terms of treated sewage and waste gas, and environmental protection requirements for factory boundary noise. And all of the environmental protection facilities could run stably, with the synchronous operation of the facilities up to the requirements.

2. Fujian Sanjiang Packaging Co., Ltd.

Strictly following the requirements of "Three Simultaneities" for construction projects, Sanjiang Packaging has improved its environmental protection facilities to ensure the stable and qualified discharge of various environmental factors. The workshops are equipped with three sets of gas collection systems. As a result, its environmental protection facilities could run stably with the synchronized operation of facilities up to the requirements.

3. Tianjin SKSHU Paint Co., Ltd. (Tianjin Factory)

Strictly following the "Three Simultaneities" requirements for construction projects, it has improved its environmental protection facilities to ensure the stable and qualified discharge of various environmental factors. The workshops are equipped with three sets of down-flow dust collectors to remove the dust in the exhaust gas, and discharge is conducted after the treatment reaches the standards; a sewage treatment station has been set up for waste water from production and experiments, which when reaching the standard is discharged into the municipal sewage pipe network of the industrial park, and finally discharged into Shuangqing Waste Water Treatment Plant for centralized treatment. Also, its environmental protection facilities could run stably, and the synchronous operation of the facilities is up to the requirements.

4. Henan SKSHU Paint Co., Ltd. (Henan Factory)

Strictly following the requirements of the "Three Simultaneities" for construction projects, it has built various environmental protection facilities to ensure the stable and qualified discharge of various environmental factors. A set of bag-type pulse dust collectors are built in the workshops to remove the dust in the exhaust gas and discharge it after reaching the standard; also, a sewage treatment station is set up to treat the waste water from reactors, workshop floors and laboratories, which, after reaching the standards, will be discharged to Nanzhao County Sewage Pumping Station and finally to Nanzhao County Sewage Treatment Plant for centralized treatment. Its protection facilities could run stably, and the synchronous operation of the facilities meets the requirements.

5. Sichuan SKSHU Paint Co., Ltd. (Sichuan Factory)

Its environmental protection facilities were equipped in strict accordance with the requirements of the "Three Simultaneities" for construction projects and of the environmental impact report. The dust-containing gas produced during the production at the water-based paint workshops is discharged according to the standards after being treated by sedimentation filter cartridge dust collectors; the organic waste gas containing dust produced in the oil-based paint workshops is pre-treated by down-flow filter cartridge dust collectors, treated by molecular sieve adsorption and concentration wheels + RTO waste gas treatment facilities, and discharged after it is up to the Integrated Emission Standard for Air Pollutants (GB16297-1996), Sichuan Emission Control Standard for Volatile Organic Compounds (DB51/2377-2017) and Emission Standards for Odor Pollutants (GB 14554-93). Moreover, the waste water and domestic sewage in the factory are treated by the sewage treatment stations in the factory. The waste water from production is treated by "efficient air flotation+micro electrolysis", and then treated by "anaerobic biofilter+biological contact oxygen" together with domestic sewage. After reaching the third grade standards in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996), it enters the Third Sewage Treatment Plant of Qionglai City through the municipal sewage pipe network for treatment before discharging into the Xiejiang River.

III. Types, Quantities and Destinations of Pollutants Discharged

1. Types, quantities and destinations of pollutants discharged by SKSHU Paint Co., Ltd. (Putian Factory)

(1) The main pollutants discharged from waste gas include non-methane total hydrocarbons, benzene, toluene, xylene, particulate matters, SO2 and nitrogen oxides, and the emission test data on exhaust from the main workshops are shown in the following table:

Notes:

1. Source of test data: Test Reports of Centre Testing International dated June 27, 2018 (No.:EDD11K001314) and August 31, 2018 (No.:EDD11K001548aR1a)

2. After treatment by the company's sewage treatment stations, the sewage is discharged into the municipal sewage pipe network and merged into the Minzhong Waste Water Treatment Plant for centralized treatment:

(1)Source of test data: Test Report of Centre Testing International on June 29, 2018 (EDD11K001339)

2. Types, Quantities and Destinations of Pollutants Discharged by Fujian Sanjiang Packaging Co., Ltd.

The main pollutants discharged from waste gas include benzene, toluene and xylene.

Note: Source of test data: Test report of Centre Testing International issued on August 10, 2018 (No.:EDD11K001549)

3. Types, Quantities and Destinations of Pollutants Discharged by Tianjin SKSHU Paint Co., Ltd. (Tianjin Factory)

(1) The main pollutants discharged by waste gas include non-methane total hydrocarbons and particulate matters.

Note: Source of test data: Beijing Hangfeng Zhongtian Testing Technology Service Co., Ltd on June 20, 2018 (No. HF1806267)

(2) After treatment by the sewage treatment stations of the company, the sewage is discharged into the municipal sewage pipe network and merged into Shuangqing Waste Water Treatment Plant for centralized treatment:

Note: Source of test data: Tianjin Yunmeng Testing Technology Service Co., Ltd. on June 8, 2018 (No. YMBG18060802)

4. Types, Quantities and Destinations of Pollutants Discharged by Sichuan SKSHU Paint Co., Ltd. (Sichuan Factory)

(1) The main pollutants discharged by waste gas include non-methane total hydrocarbons and particulate matters.

Note: Sources of test data: Monitoring Report on Environmental Protection Assessment and Approval after Completion of Paint Production and Supporting Project (60,000t/a Emulsion Paints, 50,000t/a Natural Stone and Texture Paints, 30,000t/a Putty Powder and 700t/a Water-based Wood Paint Production Lines) of Sichuan SKSHU Paint Co., Ltd., and Monitoring Report on Environmental Protection Assessment and Approval after Completion of Paint Production and Supporting Project (15,000t/a Water-based Adhesives, 12 million Packaging Cans/a, 29,300t/a Wood Paints and 5,000t/a Curing Agents Production Lines) of Sichuan SKSHU Paint Co., Ltd.

(2) After reaching the standard through the sewage treatment station of the company, the sewage will be discharged into the Third Sewage Treatment Plant of Qionglai City through the municipal pipe network for treatment. Data on main pollutants detected are shown in the following table:

Note: Source of test data: Monitoring Report on Environmental Protection Assessment and Approval after Completion of Paint Production and Supporting Project (15,000t/a Water-based Adhesives, 12 million Packaging Cans/a, 29,300t/a Wood Paints and 5,000t/a Curing Agents Production Lines) of Sichuan SKSHU Paint Co., Ltd.

5. Types, Quantities and Destinations of Pollutants Discharged by Henan SKSHU Paint Co., Ltd. (Henan Factory)

(1) The main pollutants discharged by waste gas include non-methane total hydrocarbons and particulate matters.

Note: Sources of testing data: Testing Report of Henan Micrometer Testing Technology Co., Ltd. on June 26, 2018 (testing values of latex paint workshops and texture workshops), and Testing Report of Nanyang Guangzheng Detection Technology Co., Ltd. (exhaust gas index data of can making workshops)

(2) After treatment by the sewage treatment stations of the company, the sewage is discharged into the sewage pumping station of Nanzhao County Industrial Agglomeration Zone, and finally discharged into Nanzhao County Sewage Treatment Plant for centralized treatment. Data on main pollutants detected are shown in the following table:

Note: Source of test data: Test Report by Henan Micrometer Testing Technology Co., Ltd. on June 24, 2018

IV. Assessment of Environmental Impact on Construction Projects and other Administrative Licensing on Environmental Protection

1. SKSHU Paint Co., Ltd.

2. Sichuan SKSHU Paint Co., Ltd.

3. Tianjin SKSHU Paint Co., Ltd.

4. Henan SKSHU Paint Co., Ltd.

5. Anhui SKSHU Paint Co., Ltd.

V. Emergency Plans on Environmental Emergencies

With reference to Guidelines for Preparing Environmental Emergency Plans for Petrochemical Enterprises and Information Reporting Methods for Environmental Emergencies, all 3TREES factories have prepared their own Emergency Plans for Environmental Emergencies, which have been reviewed by experts and reported to the local environmental protection bureaus and placed in the official archives.

The drills conducted according to emergency plans in 3TREES factories mainly include: (1) Each workshop organizing safety activities or training twice a month; (2) Organizing large-scale comprehensive emergency drills for key devices and parts at least once a year. For example: 3TREES (Putian Factory) held an RTO device fire emergency rescue and environmental emergency response drill in May 2018; 3TREES (Putian Factory) held early warnings of raw material leakage in the storage tank area and the on-site rescuing drill against fire accidents in November 2018; 3TREES (Tianjin Factory) staged an emergency drill for large-scale leakage accidents in June 2018; 3TREES (Henan Factory) conducted workshop emergency handling and emergency evacuation drills in June 2018; 3TREES (Sichuan Factory) organized an emergency rescue drill for solvent leakage and fire accidents in pump room of raw material storage tank area in May 2018; and 3TREES (Sichuan Factory) organized an emergency drill for vinyl acetate leakage and fire accidents in white glue workshop in November 2018 .

According to the requirements of relevant laws and regulations, Sichuan SKSHU Paint Co., Ltd. conducted independent environmental protection assessment and approval of the coating production and supporting projects of Sichuan SKSHU Paint Co., Ltd. on February 28, 2018 (production lines for 15,000 t/a of water-based adhesives, 29,300 t/a of wood paints, 5,000 t/a of curing agents and 12 million/a of packaging cans). And according to the Regulations on Environmental Protection Management of Construction Projects, the assessment and approval of the projects are disclosed as follows.

I. Overview of the projects

The projects were approved by Qionglai Development and Reform Bureau for filing (Record No.: 51018311410150067) on October 15, 2014, and Science and Technology Consulting Co., Ltd. of Sichuan Academy of Environmental Sciences completed the preparation of Environmental Impact Report on the Coating Production and Supporting Projects of Sichuan SKSHU Paint Co., Ltd. in January 2015, and the Environmental Protection Department of Sichuan Province gave a reply to the EIA report with the Chuan Huan Shen Pi [2015] No.89 document on February 16, 2015. And after completion of the project, the annual output of the products are: 5,000 tons of alkyd resins, 5,000 tons of curing agents, 30,000 tons of wood paints (including 22,000 tons of polyurethane paints, 500 tons of epoxy paints, 5,000 tons of polyester paints, 1,800 tons of UV curing paints, 700 tons of water-based wood paints), 15,000 tons of water-based adhesives, 50,000 tons of natural stone texture paints, 60,000 tons of emulsion paints, 30,000 tons of putty powders, and 12 million packaging cans. Also according to the Special Report on Environmental Impact Assessment of Adjustment and Change of Waste Gas Treatment Measures in Paint Production and Supporting Projects of Sichuan SKSHU Paint Co., Ltd. compiled by Sichuan Ring Science & Technology Co., Ltd., these projects were to be implemented in two phases. During the first phase, production lines for 50,000 t/a of natural stone texture paints, 60,000 t/a of emulsion paints, 30,000 t/a of putty powders and 700 t/a of water-based wood paints would be built, and was scheduled to complete independent assessment and approval in November 2017. For the second phase, the construction of production lines for 15,000 t/a of water-based adhesives, 29,300 t/a of wood paints, 12 million pieces/a of packaging cans and 5,000 t/a of curing agents would start in July 2015 and end in June 2017.

The items for assessment and approval included production line, environmental protection facilities and public and auxiliary facilities for 15,000t/a of water-based adhesives, 29,300t/a of wood paints, 12 million pieces/a of packaging cans, and 5,000t/a of curing agents.

II. Implementation of requirements on environmental protection facilities and measures of the projects

The required environmental protection facilities and measures have been built and put in place according to EIA requirements, and the environmental protection facilities and measures were as follows:

1. For waste gases:

(1) Waste gases from the production line for water-based adhesives

Waste gases from the production line for water-based adhesives mainly come from the processes of materials feeding, reaction and canning. For each of the steps, gas gathering devices have been installed to collect the waste gases. The main pollutants therein are volatile organic compounds and particulates, which are continuously discharged. And the waste gases are collected intensively, treated by a set of down-flow filter cartridge dust collectors in the workshop and then by a set of molecular sieve adsorption and concentration runner +RTO devices commonly used by the factory before being discharged through an exhaust pipe of 15m in height.

(2) Waste gases from the production line for canning

The waste gas generated from the production line for cans mainly come from the welding, glue injection and coating drying. For each of the processes, gas gathering devices have been installed to collect the waste gases. And the main pollutants in the waste gases are non-methane total hydrocarbons and particulates which are continuously discharged. The waste gases are collected intensively, treated by a set of down-flow filter cartridge dust collectors in the workshop and by a set of molecular sieve adsorption and concentration runner +RTO devices used in the factory before being discharged through an exhaust pipe of 15m in height.

(3) Waste gases from the production line for wood paints

The waste gases produced in the production line for wood paints mainly come from the feeding and canning processes. For each of the processes, gas gathering devices have been installed to collect the waste gases. The main pollutants therein are non-methane total hydrocarbons, particulates, toluene and xylene, which are continuously discharged. The waste gases are collected intensively, treated by a set of down-flow filter cartridge dust collector in the workshop and by a set of molecular sieve adsorption and concentration runner +RTO devices commonly used in the factory before being discharged through an exhaust pipe of 15m in height.

(4) Waste gases from the production line for curing agents

For curing agents only a simple dilution process is involved, and the waste gases produced from the production line for curing agents mainly come from feeding and canning. For each of the processes, gas gathering devices have been installed to collect the waste gases. The main pollutants therein are non-methane total hydrocarbons, particulates, toluene and xylene, which are continuously discharged. Also the waste gases are collected intensively, treated by a set of down-flow filter cartridge dust collectors in the workshop and by a set of molecular sieve adsorption and concentration runner +RTO devices commonly used in the factory before being discharged through an exhaust pipe of 15m in height.

(5) Waste gases from boiler

A 2t/h steam boiler is designed in the project using natural gas as fuel from which the main pollutants are SO2, NOx, particulates, etc., which are discharged through an exhaust pipe of 10 meters in height.

2. Waste water:

For the project rain and waste water are separated. And the waste water mainly includes water from equipment cleaning, floor flushing and domestic sewage produced by employees in the workshops for production of water-based adhesives.

Both the waste water from production and domestic sewage will enter the sewage treatment station in the factory with a treatment capacity of 200m3/d. And water from equipment cleaning, floor washing and domestic sewage of employees in the workshop for production of water-based adhesives is discharged into the sewage treatment station together with water from the production lines for emulsion paints, water-based wood paints, natural stone texture paints, water for cleaning of putty powder equipment and floor washing at the Phase I project, which is treated by "high efficiency air flotation+micro-electrolysis", and then discharged together with domestic sewage.

3. Noise and solid waste:

For the projects measures have been taken such as sound insulation, noise elimination and vibration reduction against the main sources of noise; solid wastes are collected and stored in a standardized way, and hazardous wastes are handed over to qualified units for disposal.

III. Results of assessment before approval from monitoring and investigation

According to the Environmental Protection Monitoring Report on Assessment and Approval of Construction Projects (Chuan Huan Jian Yan Zi (2017) No. YS17040) prepared by Sichuan Environmental Monitoring General Station, the conclusion of assessment and approval by monitoring is as follows:

1. Waste gases

In the systematic discharge of waste gases from the projects, the waste gases from wood paint, curing agent, tank making and water-based adhesive workshops are first treated by the sedimentation filter cartridge dust collector in their respective workshop, then treated by a set of molecular sieve adsorption and concentration runner +RTO devices commonly used in the factory before discharge through an exhaust pipe of 15m in height so that the emission concentration and emission rate of non-methane total hydrocarbons and particulates in the exhaust gases are up to the requirements of Class II standard in Table 2 of Comprehensive Emission Standard of Air Pollutants (GB16297-1996).

In the unsystematic emissions of exhaust from the projects, the emission concentrations of non-methane total hydrocarbons and particulates’ unsystematic exhaust at the downwind of the plant boundary of the projects are all up to the requirements of Table 2 "concentration limits to be observed by unsystematic monitoring" of Comprehensive Emission Standard of Air Pollutants (GB16297-1996).

2. Waste water

The emission concentrations of hydrogen ions, suspended solids, COD and BOD5 in the waste water discharged from the sewage station in the factory of the projects are all up to Class III standard in Table 4 of Integrated Wastewater Discharge Standard (GB8978-1996).

3. Noise

The daytime noise at each monitoring point outside the factory boundaries of the projects are up to the requirements of Class III standard of Emission Standard for Industrial Enterprises Noise at Boundary (GB12348-2008).

4. Solid wastes

The solid wastes from the projects include filtered residues, waste packaging materials, sewage sludge and domestic garbage from employees. And the assessment for acceptance and monitoring indicated that the collection and disposal of solid wastes at the projects were inspected, temporary storage rooms for general industrial solid wastes and hazardous wastes were built, and "three prevention" measures were taken. Solid waste storage was classified and stacked according to relevant specifications. The filtered residues and sewage station sludge in hazardous wastes are entrusted to Sichuan Zhongming Environmental Protection Co., Ltd. for disposal, and the packaging barrels for waste raw materials are entrusted to Sichuan West Poly Xin Chemical Packaging Co., Ltd., with which an entrusted disposal agreement has been signed; garbage from daily life shall be uniformly removed by the sanitation department.

5. Control on total amounts

The total amount of pollutants discharged at the projects has not gone beyond the requirements of EIA for assessment and approval.

6. Checks on environmentally sensitive buildings within the circumference of healthy protection

The assessment for approval involved a distance of 700 meters for sanitary protection outside the boundaries of the wood paint workshop. And the field investigation indicated that there are neither permanent residents nor environmental sensitive points within the circumference for protection.

7. Survey on public opinions

A total of 30 questionnaires for public opinion were distributed and 30 valid replies were recovered. And the statistics denoted that 30 respondents were satisfied or basically satisfied with the environmental protection on the projects.

8. Inspection on emergency plan against environmental risks and risk prevention measures

The company has formulated The Emergency Plan for Environmental Emergencies of Sichuan SKSHU Paint Co., Ltd., which has been filed with Qionglai Environmental Protection Bureau, by which an emergency team has been set up, and prevention and emergency measures have been defined against emergencies such as leakage of hazardous chemicals. In addition, environmental risk prevention facilities and emergency treatment measures of the projects are integrated into the unified management of the whole plant.

IV. Conclusion on the Assessment

To sum up, the environmental assessment and approval procedures for the production line projects of 15,000 t/a of water-based adhesives, 29,300 t/a of wood paints, 12 million piece/a of packaging cans and 5,000 t/a of curing agents to be made by Sichuan SKSHU Paint Co., Ltd. are in place, and its management of environmental protection is up to the relevant requirements. Moreover, the supporting facilities and measures for environmental protection have been built and implemented according to the requirements of the environmental assessment. And the measured pollutants are up to the standards and the requirements for independent assessment of environmental protection are met after the completion of the projects. Hence the recommendation for passage of the assessment.

V. Publicity

Laws and regulations on the assessment before approval of projects to be constructed require that the publicity period of the projects is from March 1, 2018 to March 31, 2018, during which time all units and individuals are entitled to report their opinions to our company in written form and the report shall be dealt with.

Comments to be received by: Sichuan SKSHU Paint Co., Ltd.

Address: No.35 Yangheng 4th Road, Qionglai Industrial Park, Tianfu New District, Qionglai City, Sichuan Province

Zip code: 611534

Tel: 028-69993716

top

Marketing Network

download center

media